Blow molding machines play a pivotal role in various industries, and selecting the right supplier and manufacturer is crucial for success. In this comprehensive guide, we’ll delve into the intricacies of Blow Molding Machine Supplier, the key features to consider, and how to choose the best supplier for your needs.

Blow molding machines are instrumental in the production of a wide range of products, from bottles and containers to automotive components. The process involves shaping molten plastic into a hollow form, and the quality of the machine directly impacts the final product. Whether you’re in the market for a new machine or considering a switch in suppliers, this guide will help you navigate the critical decision-making process.

Understanding Blow Molding Machines

Before diving into supplier selection, it’s essential to understand the basics of blow molding. This section will provide an overview of the blow molding process and the different types of machines available, setting the foundation for informed decision-making.

Key Features to Look for in a Blow Molding Machine

Not all Blow Molding Machine Manufacturer are created equal. We’ll explore the key features that differentiate machines, such as production capacity, material compatibility, and automation capabilities. Understanding these factors will guide you in choosing a machine that aligns with your production requirements.

Choosing the Right Blow Molding Machine Supplier

Selecting the right supplier is as crucial as choosing the right machine. This section will outline the importance of a reliable supplier and highlight the factors to consider during the selection process. From reputation to delivery timelines, we’ll cover it all.

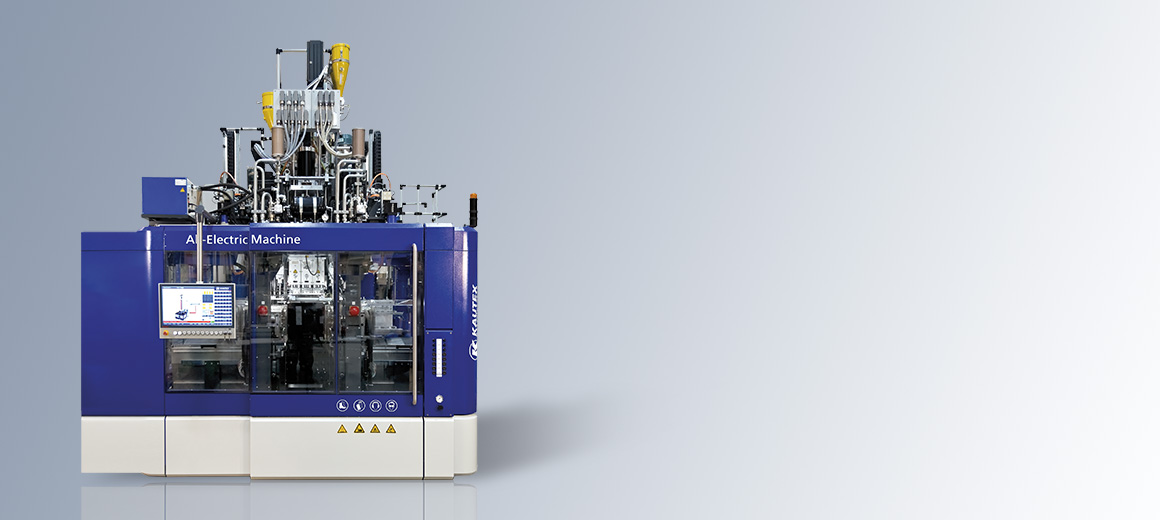

Top Blow Molding Machine Manufacturers

In this section, we’ll showcase some of the industry’s top manufacturers. By understanding their offerings and reputation, you can make an informed decision when narrowing down your options.

Quality Assurance in Blow Molding

Quality is paramount in manufacturing. We’ll explore the importance of quality assurance in blow molding and provide insights into how to ensure the machine you choose meets the required standards.

Cost Considerations

While cost is a significant factor, it’s essential to strike a balance between upfront expenses and long-term cost-effectiveness. We’ll guide you through the considerations that go beyond the initial price tag.

Customer Reviews and Testimonials

Real-world experiences matter. Learn how to leverage customer reviews and testimonials to gain insights into a supplier’s reliability and the performance of their machines.

After-Sales Support and Services

A machine’s lifecycle involves more than just its purchase. We’ll discuss the significance of after-sales support, including warranty, maintenance, and troubleshooting services.

Technological Advancements in Blow Molding

Stay ahead of the curve by understanding the latest technological trends in blow molding. From improved efficiency to enhanced capabilities, we’ll cover the advancements shaping the industry.

Eco-Friendly Blow Molding Solutions

As sustainability becomes increasingly important, we’ll explore how suppliers and manufacturers are contributing to eco-friendly solutions in blow molding.

Global Market Trends in Blow Molding

Gain insights into current market trends and forecasts, allowing you to make decisions that align with the industry’s trajectory.

Case Studies: Successful Implementations

Real-world success stories highlight the impact of choosing the right machine and supplier. Explore case studies that showcase the positive outcomes of strategic decisions.

Challenges and Solutions in Blow Molding

No industry is without challenges. We’ll examine common issues in blow molding and present innovative solutions that can contribute to your success.

Conclusion

In conclusion, the decision to choose a blow molding machine supplier is multifaceted. By carefully considering the factors discussed in this guide, you can make an informed decision that sets the stage for success in your industry.